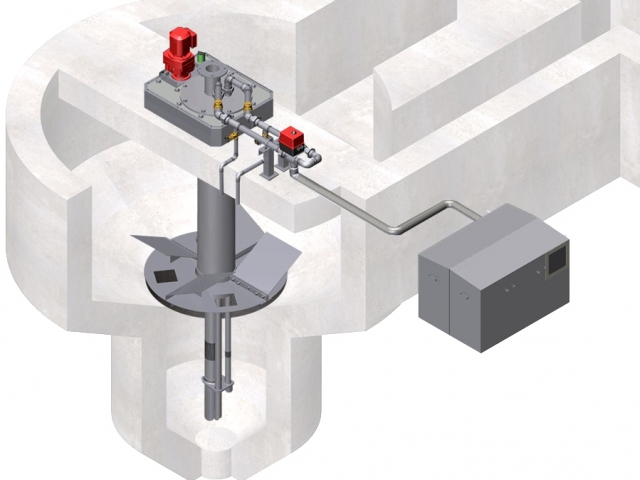

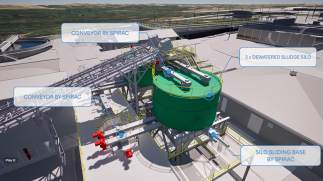

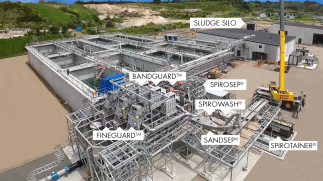

This Wastewater Treatment Plant treats 57 ML/day of primary sewage from an EP of 210,000. The plant was expanded and commissioned in Dec 2005. The new SPIRAC® systems include three SPIROSEP Grit Vortex chambers, hydro cyclones, a SANDSEP® grit classifier, two twin SPIROWASH® screening washer units, a sluice and conveying system, and two SPIROTAINERs®.

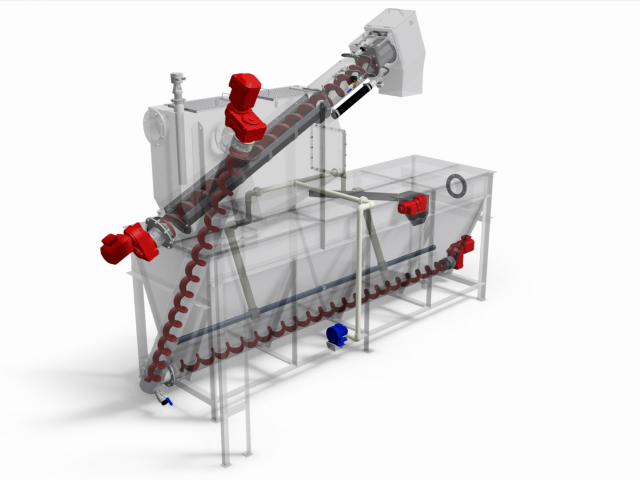

Grit is pumped from the SPIROSEP® Vortex Grit chambers through three hydrocyclones and discharged into a single SANDSEP screening classifier. This feeds a common screenings/grit collection conveyor to fill two SPIROTAINERs®. Screenings from a band screen are transported via launder to twin SPIROWASH® screw-compactors which wash and compact the screenings before elevating the screenings into the collection conveyor. Automatic bifurcated chutes allow bypass to overflow bins if the SPIROTAINER® is full or absent. The system is completely automated, allowing auto bin changeover, duty/standby operation of the SPIROWASH®, and full monitoring and functional control.

This screenings and grit plant upgrade in 2006 included the following SPIRAC equipment:

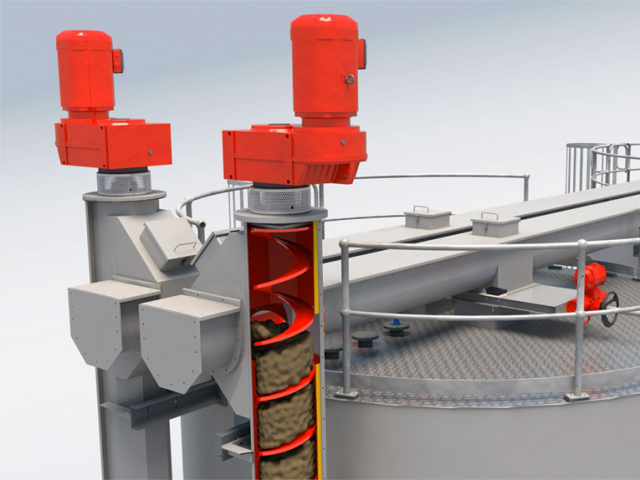

- SPIROSEP® Vortex grit systems (3) with Grit pump extraction

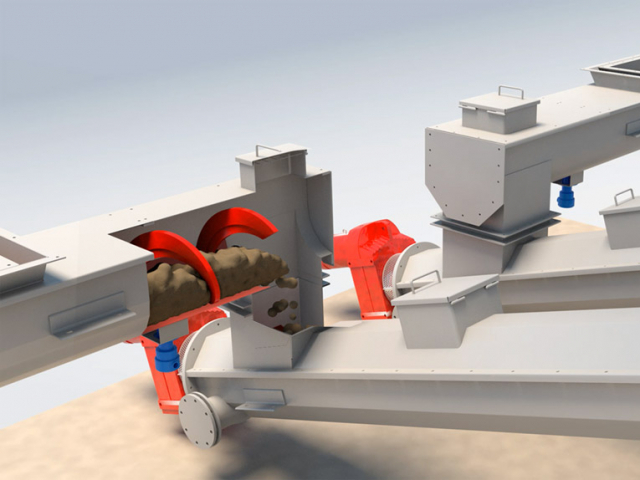

- Launder (sluice) system to transfer screenings and wash water from screens to SPIROWASH units

- SPIROWASH® Duplex (2) for high-capacity screenings washing and compaction

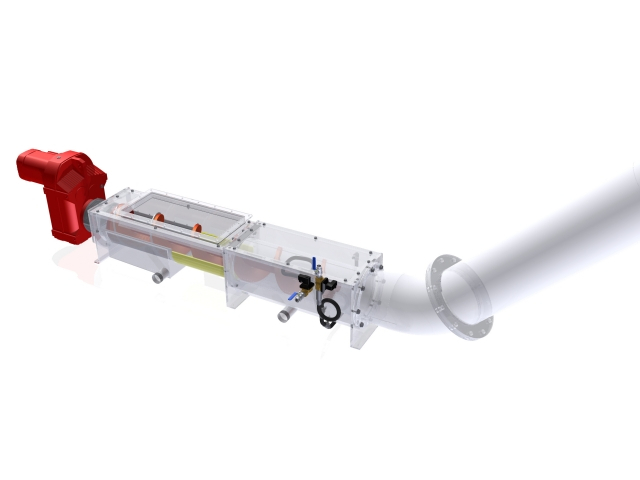

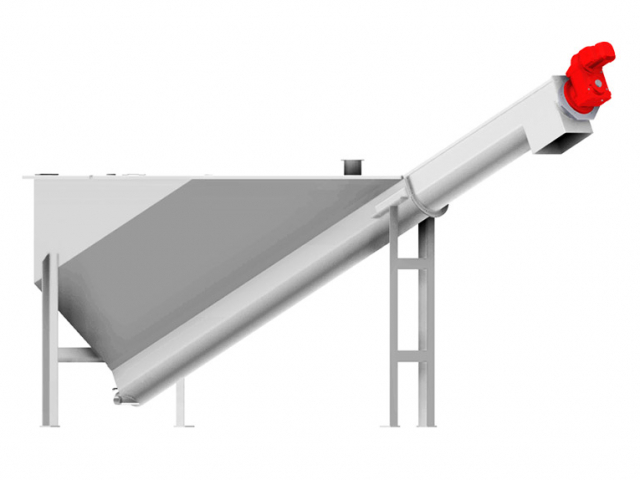

- SANDSEP® Grit classifier fed by three hydro cyclones

- Combined screenings and grit transfer conveyor

- Diverter chutes on screenings and grit feed to the conveyor for emergency bypass

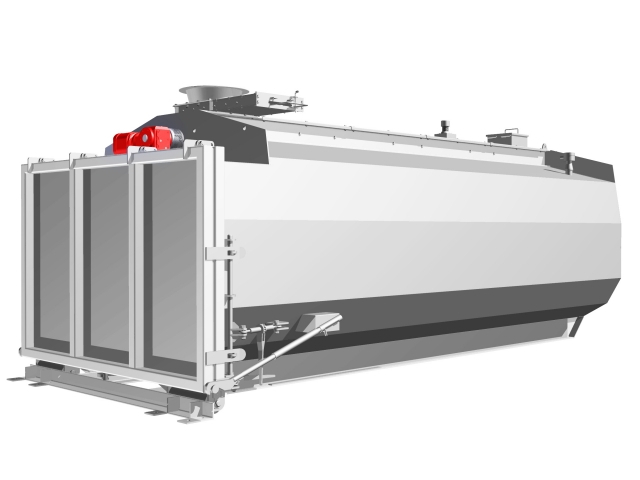

- Two SPIROTAINERS® for storage, odour containment and road transport