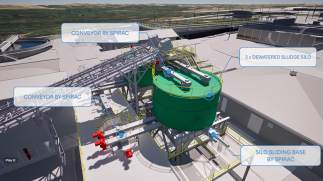

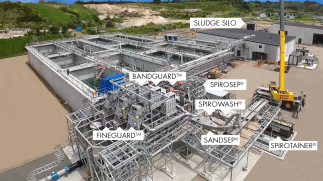

- Shaftless Spiral Conveyors

Solids handling systems are crucial for process industries to avoid downtime and contain odor and mess. SPIRAC's Shaftless Spiral Conveying Systems are ideal for wastewater material handling systems.

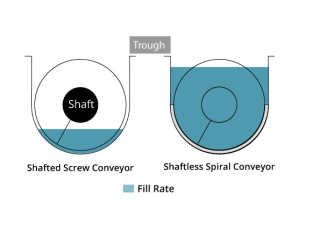

Shaftless spiral conveyors lack a center shaft, allowing for a larger cross-section and higher fill rates compared to shafted conveyors. They use less than half the cross-sectional area for the same capacity and efficiently move dense, wet materials due to their high torque capability.

Higher fill rates make shaftless spiral conveyors more efficient at transporting sludge, minimizing shearing and maintaining sludge rheology over long runs and vertical lifts.Shaftless spiral conveyors, work better with high fill rates above 60%.

Selecting the right spiral type and screw conveyor size is crucial. For easy-to-transport material at a horizontal or slight incline, a single-section spiral is recommended. For sticky materials, spirals with inserts and a scraping edge are ideal.

SPIRAC offers a range of element cross-sections, spiral pitches, and diameters to match your application's requirements. Talk to our engineers about the best spiral type and screw size for your needs.