- Asia Pacific News

- Energy Savings

- Europe News

- Industrial Solutions

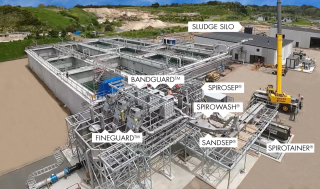

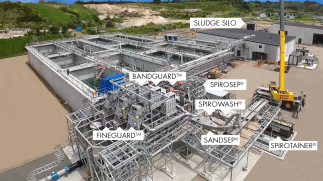

- Municipal Solutions

- North America News

At SPIRAC, environmental responsibility is more than a commitment—it’s an integral part of how we design our bulk material handling systems. Our range of silo technologies—including Sliding Frame and Live Bottom—is engineered not only to deliver reliable performance but also to reduce environmental impact across wastewater treatment and industrial operations.

Our Storage Options

SPIRAC offers a flexible portfolio of silo solutions to meet a wide range of material handling needs:

1. Sliding Frame Silos/Receival Bunkers

An efficient discharge system designed for non‑free‑flowing bulk materials.

A hydraulically driven frame breaks material bridges and directs product toward the shaftless spiral extraction screw.

- Available in round or rectangular configurations

- Ideal for flat-bottom silos

- Suitable for capacities up to 1,000 m³

- Works well in wastewater, biomass, and industrial solids handling

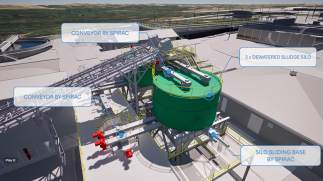

2. Live Bottom Silos/Receival Bunkers

Designed for the most cohesive and problematic materials.

Multiple low‑speed shaftless spiral (screw) conveyors provide continuous material movement, preventing bridging and rat-holing.

- Highly reliable for sticky sludge

- Low wear due to slow RPM

- Ideal for wastewater treatment plants and heavy sludge applications

When to Choose Sliding Frame vs. Live Bottom

Sliding Frame

(For Non‑Free‑Flowing Materials)

Use a Sliding Frame when material tends to bridge but is not extremely sticky. A hydraulically powered frame breaks up buildup and helps maintain reliable discharge flow.

Advantages

- Simple design with few moving parts

- Minimal maintenance and low energy use

- Excellent reliability for daily operations

- Ideal for facilities requiring FIFO discharge patterns

Typical Materials

- Dewatered sludge

- Solid waste

- Wood chips

- Cellulose, gypsum, paper sludge

- Other non‑free‑flowing bulk solids

Live Bottom

(For Highly Sticky or Difficult Materials)

Use a Live Bottom when handling extremely sticky, cohesive, or high‑moisture materials. Multiple spiral screws ensure continuous movement inside the silo.

Advantages

- Superior bridging prevention

- Low wear due to slow shaftless spiral (screw) conveyor rotation

- Inspections typically required only every 5–10 years

- Component lifespan up to 20 years

Typical Materials

- Sticky dewatered sludge

- High-moisture sludge cake

- Materials prone to rat-holing or severe bridging

Quick Comparison

| Feature | Sliding Frame | Live Bottom |

|---|---|---|

| Best For | Non‑free‑flowing, moderately sticky materials | Extremely sticky, cohesive materials |

| Mechanism | Hydraulic frame breaking bridges | Multiple screws ensuring continuous movement |

| Maintenance | Very low | Low, with more moving components |

| Power Use | Low | Low RPM across multiple screws |

| Industries | Waste, biomass, sludge handling | Wastewater treatment |

| Bridging Prevention | Good | Excellent |

Environmental Benefits

-

Energy Efficiency & Lower Carbon Impact: Both systems use slow‑speed, high‑torque drives that significantly reduce power demand compared to traditional discharge systems—lowering operational costs and carbon emissions.

-

Optimized Material Flow: Minimized bridging means fewer blockages. This reduces dust emissions, material degradation, and manual intervention, enhancing both environmental control and workplace safety.

-

Durability & Extended Service Life: SPIRAC's outloading systems are constructed from high‑quality materials and engineered for longevity. Fewer replacements mean reduced resource consumption and lower environmental impact long‑term.

-

Supporting Circular Economy Goals: Reliable discharge of biosolids and recyclable materials helps convert waste into valuable products, supporting circular economy principles and sustainable resource recovery.

A Sustainable Future in Material Handling

SPIRAC remains committed to aligning our technologies with global sustainability goals. Our complete range of silo solutions - helps industries reduce environmental impact while maintaining exceptional performance and reliability.